1. Product Overview

Dear customer, welcome to purchase our company's independently developed high-efficiency drawer-type LED UV curing cabinet. This product uses high-quality and high-power LED ultraviolet light bulbs, with strong light emission and a lifespan of over 20,000 hours. The energy consumption is only 10% of that of traditional mercury lamps, making it energy-efficient and environmentally friendly. It is equipped with an intelligent timing system, which is easy to operate and has extremely high curing efficiency. It is an ideal alternative to traditional mercury lamp curing equipment. It is widely used in manicure phototherapy, 3D printing post-processing, printing inks, electronic adhesives, scientific research experiments, and other fields.

2. Key Product Features and Advantages

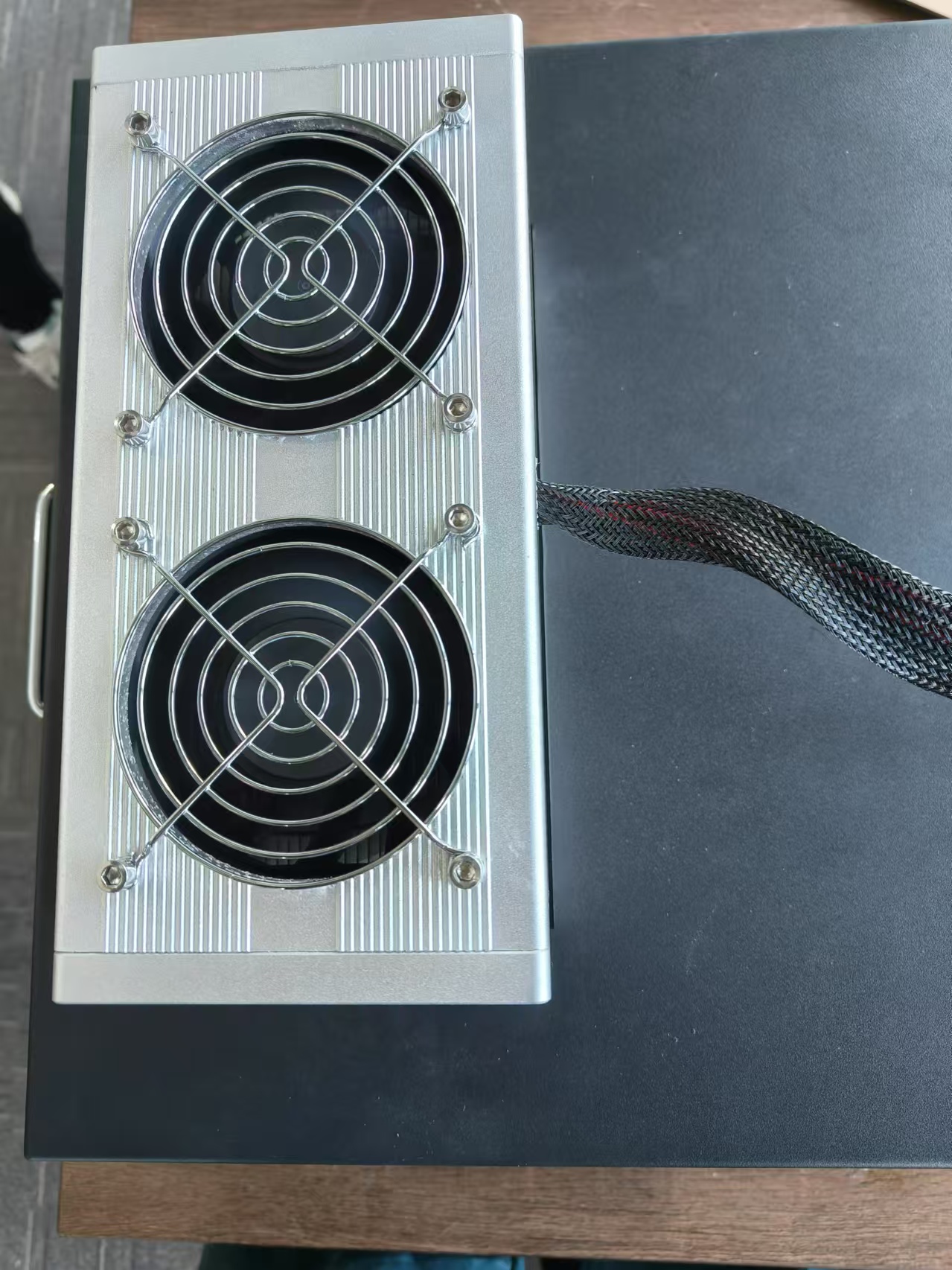

High-efficiency energy-saving curing: Utilizing imported LED lamp cores, it starts instantly and is ready to use right away, without the need for preheating. The energy is concentrated, enabling the curing process to be completed within seconds, significantly enhancing production efficiency. With extremely low energy consumption, it can save a considerable amount of electricity over the long term.

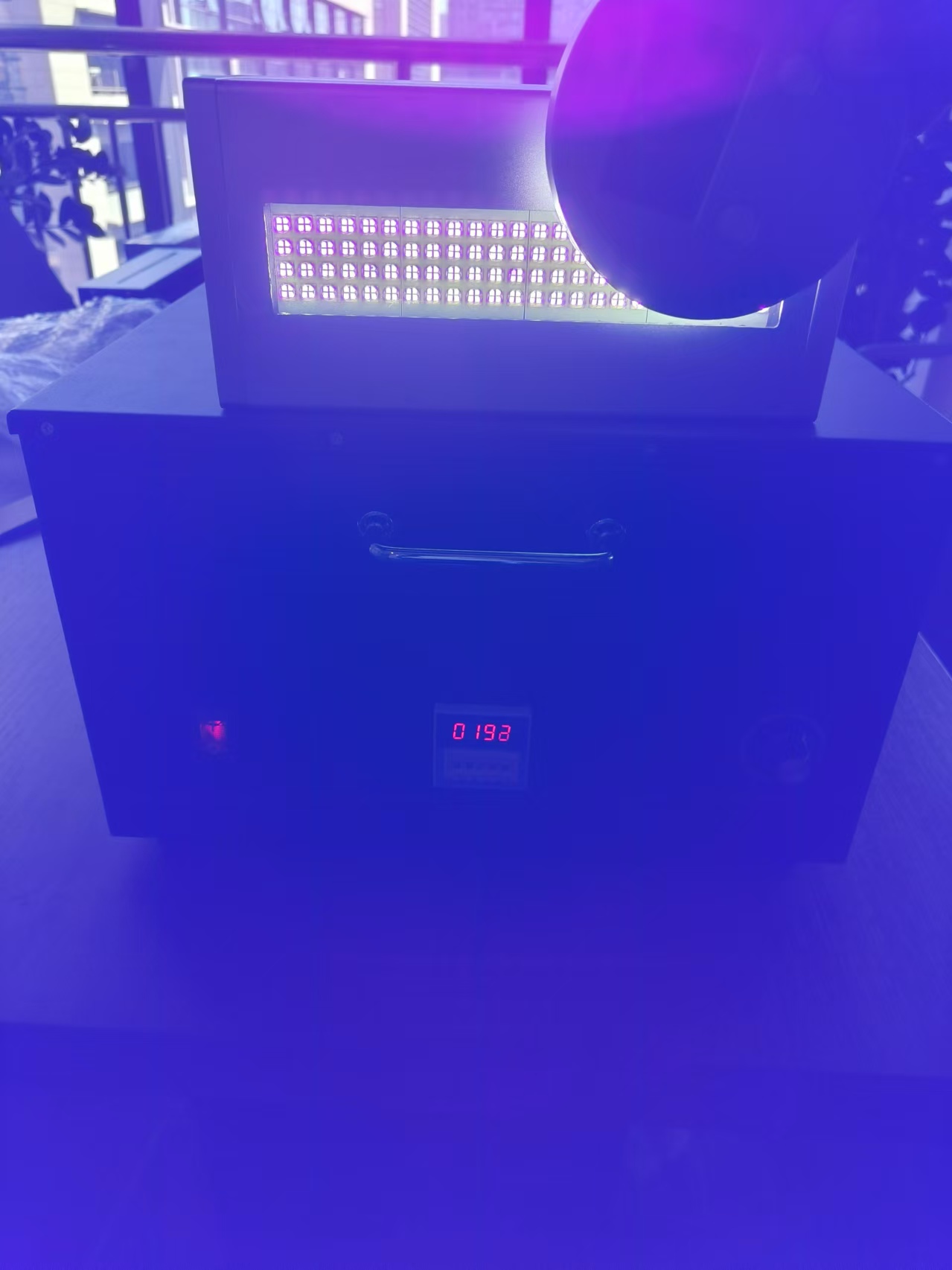

Safe and reliable design: Drawer-type structure, effectively preventing ultraviolet leakage, protecting the eyes and skin of operators. Built-in safety interlock switch, the UV lamp will automatically turn off when the drawer is opened, providing greater peace of mind during use.

Intelligent control system: Digital display, precise setting of curing time (1 - 999 seconds), automatic shutdown upon expiration of time with a beeping alert, enabling automated operation and ensuring consistent curing effect each time.

Uniform Lighting System: The professional optical design of reflectors and lamp beads ensures uniform lighting inside the box, without any blind spots, allowing all parts of the product to achieve consistent curing effects and avoiding areas that do not cure or over-cure.

Durable and sturdy material: The outer shell is made of high-quality cold-rolled steel, and the inner wall is made of aluminum alloy. It is corrosion-resistant, heat-resistant, has a sturdy structure and a long service life.

Multiple wavelengths available: We can provide a variety of mainstream wavelengths such as 365nm, 385nm, 395nm, 405nm according to your curing materials, perfectly meeting the requirements of various photosensitive resins, inks, and adhesives.

3. Technical Specifications

Product model: JLK-20050F-GHX

UV wavelength: 365nm / 395nm (optional)

Internal dimensions: 300*230*250mm (Length x Width x Height)

Timing range: 1 to 999 seconds

Power supply voltage: AC 220V / 50Hz

Overall power: Approximately 300 W

Overall dimensions: Approximately 400 * 350 * 352 mm

4. Application Areas

Beauty industry: Nail phototherapy glue, eyelash grafting adhesive.

Industrial Printing: PCB circuit board ink, coatings on metals, glasses, plastics, and the curing of labels.

3D printing: Post-curing treatment of photopolymer 3D printing models to enhance their strength and stability.

Electronic industry: Electronic component fixation, chip packaging, COB packaging, UV glue curing.

Medical research: Medical equipment assembly, laboratory sample curing, jewelry and dental model curing.

5. Services and Guarantees

Source manufacturer: Produced directly by the factory, with significant price advantages. Supports OEM/ODM customization (size, wavelength, power).

Quality Assurance: The core LED light beads are guaranteed for 2 years, the entire machine is guaranteed for 1 year, and lifetime technical support is provided.

Professional services: Offer professional technical consultation and after-sales support to help you solve problems in your application.