[Product Overview]

Dear customer, hello! Welcome to learn about our factory's independently developed and produced high-performance small LED UV curing oven.

This equipment adopts the latest generation of 365nm/395nm/405nm wavelength LED cold light source technology, specially designed for small

and medium-sized production processes. It can achieve instant curing of inks, coatings, adhesives and other materials within 1-3 seconds. It has

significant advantages such as energy conservation, environmental protection, immediate use upon startup, no thermal radiation, and long service

life. It is an ideal choice for improving your production efficiency and reducing overall costs.

【Core Selling Points and Advantages】

High-efficiency Instant Curing: Utilizing high-energy LED UV light modules, with high and stable irradiation intensity, it enables UV coatings to cure

completely within seconds, significantly enhancing production line efficiency and output.

Extra-long service life: The core LED lamp beads have a lifespan of up to 20,000 to 30,000 hours, far exceeding that of traditional mercury lamps,

significantly reducing your material replacement costs and downtime.

Energy-saving, environmentally friendly and power-saving: Compared with traditional mercury lamp curing machines, it can save energy by up to

80% or more, and it does not contain harmful substances such as mercury. It does not require preheating and can be used immediately upon startup,

meeting modern green production standards.

Cold light source technology: It generates almost no infrared thermal radiation during operation, preventing workpieces from deforming or discoloring

due to overheating. It is particularly suitable for the curing of heat-sensitive materials such as plastics, electronic components, and precision instruments.

Intelligent control system: Equipped with a digital display screen, it can precisely control the light intensity, conveyor belt speed (variable frequency speed

regulation), and curing time. The operation is simple and it meets various process requirements.

High-quality and durable design: The body is made of high-quality cold-rolled steel plate, and the conveyor belt is UV-resistant silicone rubber belt, which

runs smoothly and is long-lasting. The structure is compact, occupying a small area, and is suitable for various workshop layouts.

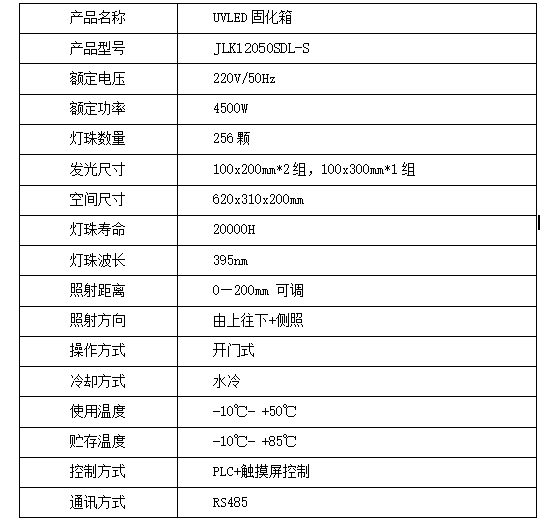

【Technical Parameters】

【Application fields】

Printing industry: UV curing of screen printing, offset printing and pad printing inks on the surfaces of mobile phone cases, PVC cards, metal plates,

glass, acrylic, etc.

• Coating industry: UV topcoat and primer curing for wooden furniture, plastic products, automotive parts, etc.

• Electronics industry: curing of green solder mask for printed circuit boards (PCBs), fixing of electronic components, and underfill adhesives for chip

packaging.

• Arts and Crafts Industry: Jewelry, epoxy resin crafts, and photosensitive resin curing for 3D printed models.

• Adhesive sealing: UV glue bonding and sealing curing for medical devices, optical lenses, glass products, etc.

Why choose us?

• Original manufacturer: Independently developed and produced, with more competitive prices and no middleman markups.

• Quality Assurance: Core components are all selected from well-known brands, with strict quality inspection and a one-year warranty provided.

Customized services: We can provide non-standard customized services based on your workpiece size and curing requirements (power, width, length,

color, etc.).

Professional services: Provide detailed technical consultation, after-sales guidance and prompt maintenance response.

Sample support: Welcome to call for consultation. We support free trial printing with sample parts.

【Purchase Information】

This product supports OEM/ODM contract manufacturing.

The specific price varies depending on the configuration and customization requirements. Please consult the customer service for an accurate quotation.

Please clarify your curing material, workpiece size and production capacity requirements before purchase, so that we can recommend the most suitable

model for you.

Final Call to Action:

Click to consult now and get your exclusive quotation plan! Start efficient production with a professional LED UV curing machine.