I. Core Principle of LED UV Curing Lamps

LED UV curing lamps are technical devices that utilize ultraviolet (UV) light to rapidly cure photosensitive materials.

The core principle is based on photochemical reactions. By using ultraviolet light of specific wavelengths (typically

365nm, 385nm, 395nm, etc.), it triggers photoinitiators in the materials to decompose and generate free radicals or

cations, thereby initiating polymerization reactions and achieving an instantaneous transformation of the material

from liquid to solid.

Key steps:

UV light emission: The LED chip converts electrical energy into high-intensity ultraviolet light through the principle of

electroluminescence.

Photoinitiator activation: After absorbing UV photons, the photoinitiator in the material decomposes into active groups

(such as free radicals).

Chain reaction: Active groups trigger the polymerization reaction of monomers or oligomers, forming a cross-linked network

structure.

Instant curing: The entire process is completed within milliseconds to seconds, without the need for traditional heating or

prolonged drying.

The differences from traditional mercury lamps:

Wavelength singularity: LED UV emits narrow-band light (e.g., 395nm ± 5nm), while mercury lamps emit multiple bands

(including UVA/UVB/UVC).

No thermal radiation: The cold light source feature of LED avoids material deformation due to heat, making it suitable for

heat-sensitive substrates.

II. Notable Advantages of LED UV Curing Lamps

Compared with traditional mercury lamp curing technology, LED UV curing lamps have revolutionary improvements in efficiency,

environmental friendliness, and cost:

Energy-saving and efficient

The electro-optical conversion efficiency is as high as 30-40% (mercury lamps only 5-10%), and energy consumption is reduced by

more than 70%.

Ready to use immediately, no preheating required, improving production line efficiency.

Environmental protection and safety

It does not contain toxic substances such as mercury and complies with environmental regulations such as RoHS and REACH.

No ozone emissions, reducing the ventilation requirements of the workshop.

Long service life and low maintenance

The lifespan of LED can reach 20,000 to 50,000 hours (mercury lamps about 1,000 hours), and maintenance costs drop sharply.

Modular design allows for the quick replacement of individual LED beads in case of failure.

Precise control

Adjustable light intensity and wavelength, suitable for different photoinitiator systems.

Local curing is achieved through lenses or reflectors to reduce interference from stray light.

Wide compatibility

It is applicable to various substrates such as plastic, glass, metal, paper, etc.

It is effective for both thin coatings (such as 3D printing resin) and thick coatings (such as ink).

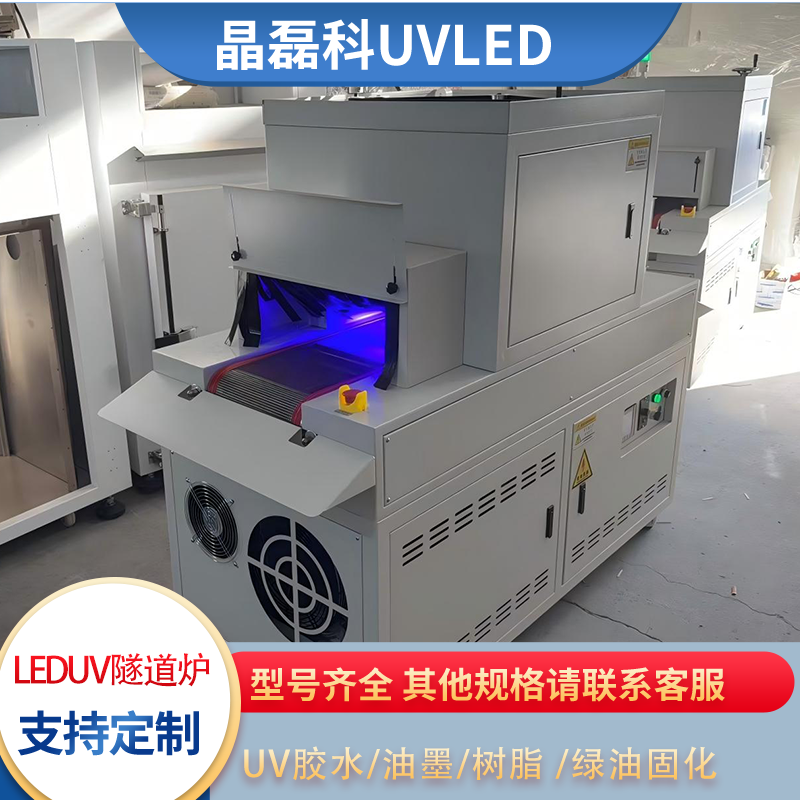

III. Detailed Industry Application Scenarios

LED UV curing technology has permeated into multiple high-value-added fields. The following are typical application scenarios:

Printing and Packaging

Application: Label printing, flexible packaging, metal can printing, UV inkjet printing.

Advantages: Instant curing increases printing speed and reduces smudging; supports high-precision patterns and special effects

(such as three-dimensional varnish).

Electronic manufacturing

Application: PCB solder mask curing, chip packaging, OCA adhesive bonding for display screens, and protection of FPC flexible

circuit boards.

Requirement: Low-temperature curing to avoid thermal damage to components, and high-precision control to ensure uniform

coating at the micron level.

automobile industry

Applications: Headlamp bonding, interior coating, glass film coating, tire marking.

Case: Tesla uses UV curing technology to achieve rapid sealing of battery packs.

Medical and Biological Sciences

Applications: Catheter coating, medical labels, contact lens manufacturing, dental filling resin curing.

Compliance: Must meet medical-grade certifications such as ISO 13485 to ensure no toxic residue.

3D Printing and Light Curing Molding

Application: Light source for SLA/DLP/LCD 3D printers.

Trend: High-power LEDs replace traditional lasers, reducing costs and increasing printing speed.

Coatings and Adhesives

Application: Wood lacquer, metal anti-corrosion coating, UV pressure-sensitive adhesive, instant bonding.

Innovation: UV and moisture dual curing technology solves the curing problem in shadow areas.

IV. Technical Challenges and Future Trends

Current Challenges:

The heat dissipation issue of high-power LEDs affects their stability.

Long-wavelength UV (such as 395nm) has limited penetration and is less efficient in curing dark materials.

Future development direction:

Higher power density: The combination of multi-chip integration and microchannel cooling technology.

Wavelength extension: Developing deep ultraviolet (UVC LED) for sterilization and semiconductor lithography.

Intelligent system: integrating spectral monitoring and AI feedback control to achieve adaptive curing.

Green materials: Develop low-toxicity, highly reactive bio-based photoinitiators.

V. Conclusion

LED UV curing lamps, with their high efficiency, environmental friendliness, and precision, are gradually replacing traditional

curing technologies and becoming the "invisible driver" of advanced manufacturing. With the advancement of materials science

and semiconductor technology, their application boundaries will continue to expand, benefiting from microelectronics to space

manufacturing. Enterprises need to assess their initial investment and long-term returns based on their own process requirements

and seize the window of opportunity for technological upgrading.