Innovation in technology drives efficient new experiences in curing.

Recently, Jinglei Ke successfully launched a new generation of high-power LED UV curing lamps. Utilizing advanced semiconductor light source technology,

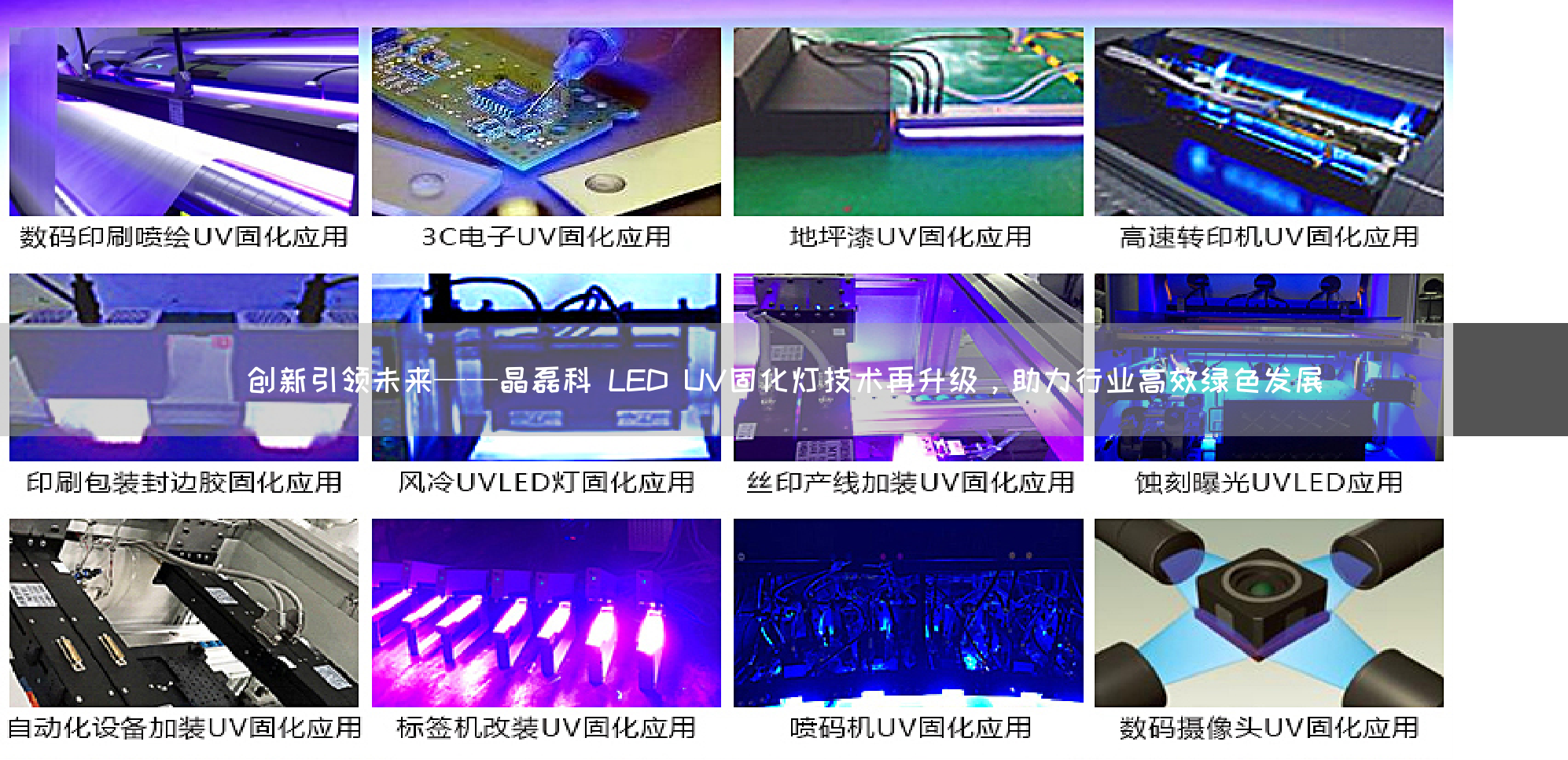

these lamps feature higher energy density, longer service life, and more precise wavelength control, enabling diverse curing needs in industries such as printing

, coating, electronics, and healthcare.

High efficiency and energy saving: Compared with traditional mercury lamps, energy consumption is reduced by over 70%, helping enterprises achieve green

production.

Ready-to-use: No preheating required. Instantly reaches maximum light intensity, increasing production line efficiency by 30%.

Intelligent control: Supports continuous dimming + remote monitoring, suitable for the requirements of automated production lines.

Industry customization, precise matching of customer needs

For different application scenarios, Jinglei Technology offers customized LED UV curing solutions:

Printing and packaging industry: Introduce 395nm highly uniform light strips to ensure rapid ink curing with no residue.

3D Printing/Electronics Industry: Develop 365nm precise curing modules, suitable for precise electronic adhesives and photopolymer molding.

Automobile/Industrial Coating: High-power multi-wavelength composite curing system, meeting the requirements for efficient curing of thick coatings.