- In terms of curing speed

- The higher the power, the faster the curing speed is usually. LED curing lamps emit light of specific wavelengths, which can excite the photoinitiators in the photocurable material to produce free radicals or cations, thereby initiating a polymerization reaction that solidifies the material. When the power is high, the number of photons that hit the surface of the photocurable material per unit time increases, and the efficiency of exciting the photoinitiators is higher, allowing the polymerization reaction to proceed more rapidly.

- For example, in the curing of dental restorative materials, high-power (such as above 1000mW/cm²) LED curing lights may only take a few seconds to fully cure the filling material, while low-power (such as 300 - 500mW/cm²) curing lights may require tens of seconds or even longer to achieve the same degree of curing.

- In terms of curing depth

- High power helps to increase the depth of cure. When photo-curable materials are cured by light, the energy of the light diminishes as it penetrates deeper into the material. High-power LED curing lights can allow the light to penetrate a greater distance within the material, still providing enough energy at deeper locations to initiate polymerization reactions.

- Taking the production of thick layers of photopolymerized 3D printing materials as an example, using a high-power LED curing lamp can achieve thicker print layer thicknesses. If the power is lower, the light energy will not be sufficient to initiate polymerization after penetrating a certain thickness of material, leading to incomplete curing and affecting the quality of the printed parts.

- In terms of curing quality

- Suitable power can ensure good curing quality. Excessive power may cause the material surface to cure too quickly, while the internal solvents and other components have no time to evaporate before being encapsulated under the cured surface layer, resulting in internal stress. This makes the cured material prone to cracking, deformation, and other issues.

- For example, in the application of UV-curable coatings, excessive power may cause the surface of the coating to quickly cure and form a hard shell, while the internal diluents and other small molecules cannot escape, ultimately leading to quality issues such as reduced adhesion and gloss. Conversely, too low power may result in incomplete curing of the material, such as insufficient hardness and poor wear resistance.

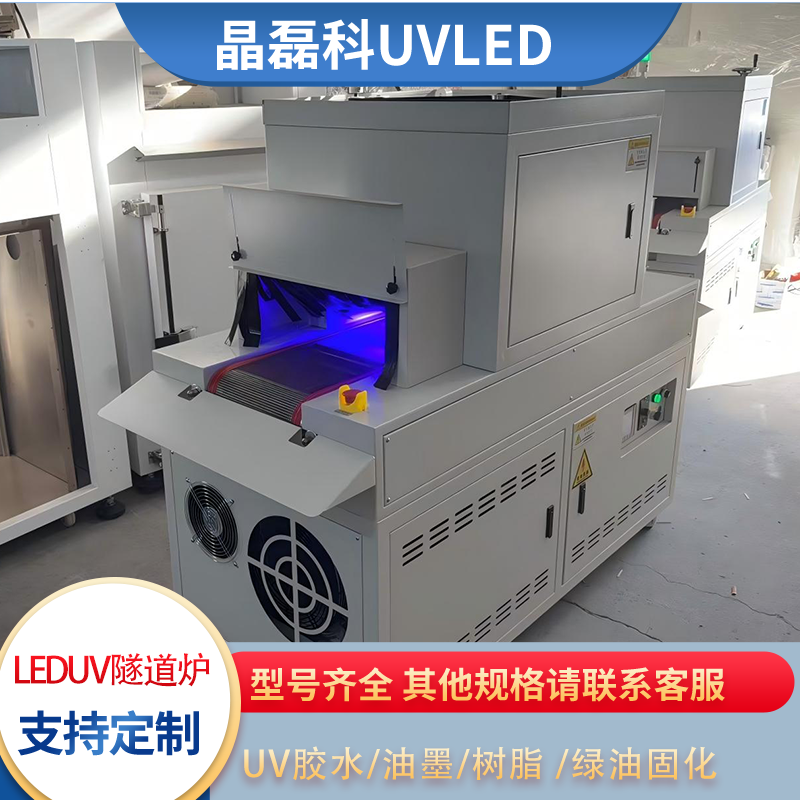

Welcome to the official website of Shenzhen Jingleike Technology Co., Ltd.

LED UV curing system Professional technical research team, industry-leading technology

Tel:+86 15338763205